Tape Innovations LLC

Reinventing

Die Cutting Solutions

to deliver precision components on time.

Application/Solution

Get a Quote

SERVICES

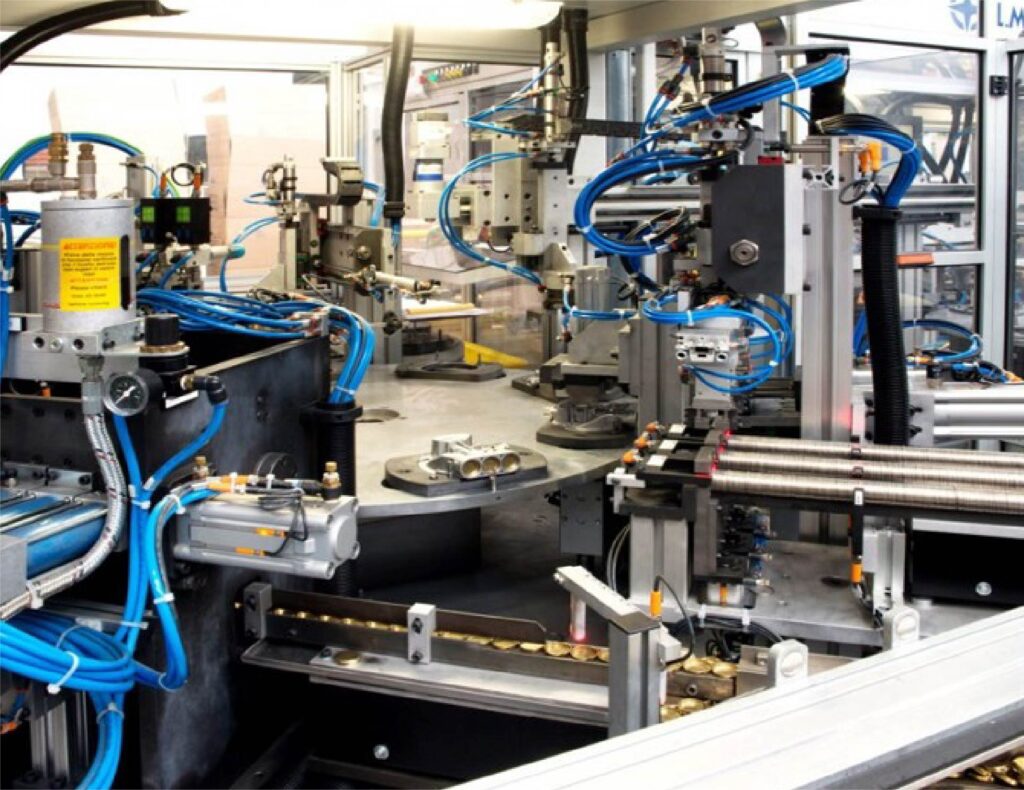

Cut to the Chase

Our diversified services start with steel rule and rotary die cutting capable of high

output production, water jet and laser cutting, router and mill work. Here’s a short

list of the processes we offer:

Applications

Applications We Support

Gasketing & Sealing

Tight, reliable seals for enclosures, housings, and mission-critical equipment.

Thermal Management

Pads, foils, and films that pull heat away from sensitive electronics.

EMI/RFI Shielding

Conductive materials that block interference and protect performance.

Vibration & Noise Dampening

Foams and elastomers that cut vibration, reduce noise, and extend product life.

Electrical Insulation

Durable, high-tolerance films and rubbers to prevent shorts and failures.

Need a custom gasket

or die-cut solution?

MATERIALS

Product Spotlight

METAL

RTJ Gaskets

Trusted Converter Partner for Global Leaders

CASE STUDIES

Enhancing Seal Performance with Rogers PORON®

INDUSTRIES

Industries Served

standards.

Aerospace

Tight, reliable seals for enclosures, housings, and mission-critical equipment.

Medical

Pads, foils, and films that pull heat away from sensitive electronics.

Energy

Conductive materials that block interference and protect performance.

Industrial

Foams and elastomers that cut vibration, reduce noise, and extend product life.

Electronics

Tight, reliable seals for enclosures, housings, and mission-critical equipment.

Defense

Pads, foils, and films that pull heat away from sensitive electronics.

HVAC

Conductive materials that block interference and protect performance.

Automotive

Foams and elastomers that cut vibration, reduce noise, and extend product life.

Certifications & Compliance